Planning and Preparation

Building a rocking chair from scratch is a rewarding endeavor, but it requires careful planning and preparation. Taking the time to get everything right at the beginning will make the process smoother and lead to a more satisfying outcome.

Choosing the Right Wood

Selecting the right wood for your rocking chair is crucial. It will determine the strength, durability, and aesthetics of your finished piece. Consider the following factors:

- Hardness: Hardwoods, like oak, maple, and cherry, are strong and resistant to wear and tear, making them ideal for rocking chairs that will receive regular use.

- Grain Pattern: The grain pattern of the wood can significantly impact the appearance of your chair. For example, oak has a distinctive grain pattern that adds character to furniture.

- Color: The color of the wood can influence the overall look of the chair. Consider the desired aesthetic and how the wood will age over time.

- Availability: Some woods are more readily available than others, which may impact your budget and construction timeline.

Selecting the Right Tools

Having the right tools is essential for building a quality rocking chair. It’s important to invest in tools that are appropriate for the task and ensure they are in good working condition. Here’s a list of essential tools:

- Saw: A table saw, circular saw, or miter saw will be necessary for cutting the wood to size.

- Router: A router is useful for shaping the edges and creating decorative details.

- Drill: A drill with a variety of bits is essential for drilling pilot holes and attaching hardware.

- Sandpaper: Sandpaper in various grits is needed to smooth the wood surfaces and prepare them for finishing.

- Clamps: Clamps are crucial for holding the pieces of wood together while gluing or assembling.

- Measuring Tape: A measuring tape is essential for accurate cutting and assembly.

- Level: A level ensures that the chair is built with straight and even surfaces.

- Safety Gear: Always wear safety glasses, ear protection, and gloves when working with power tools.

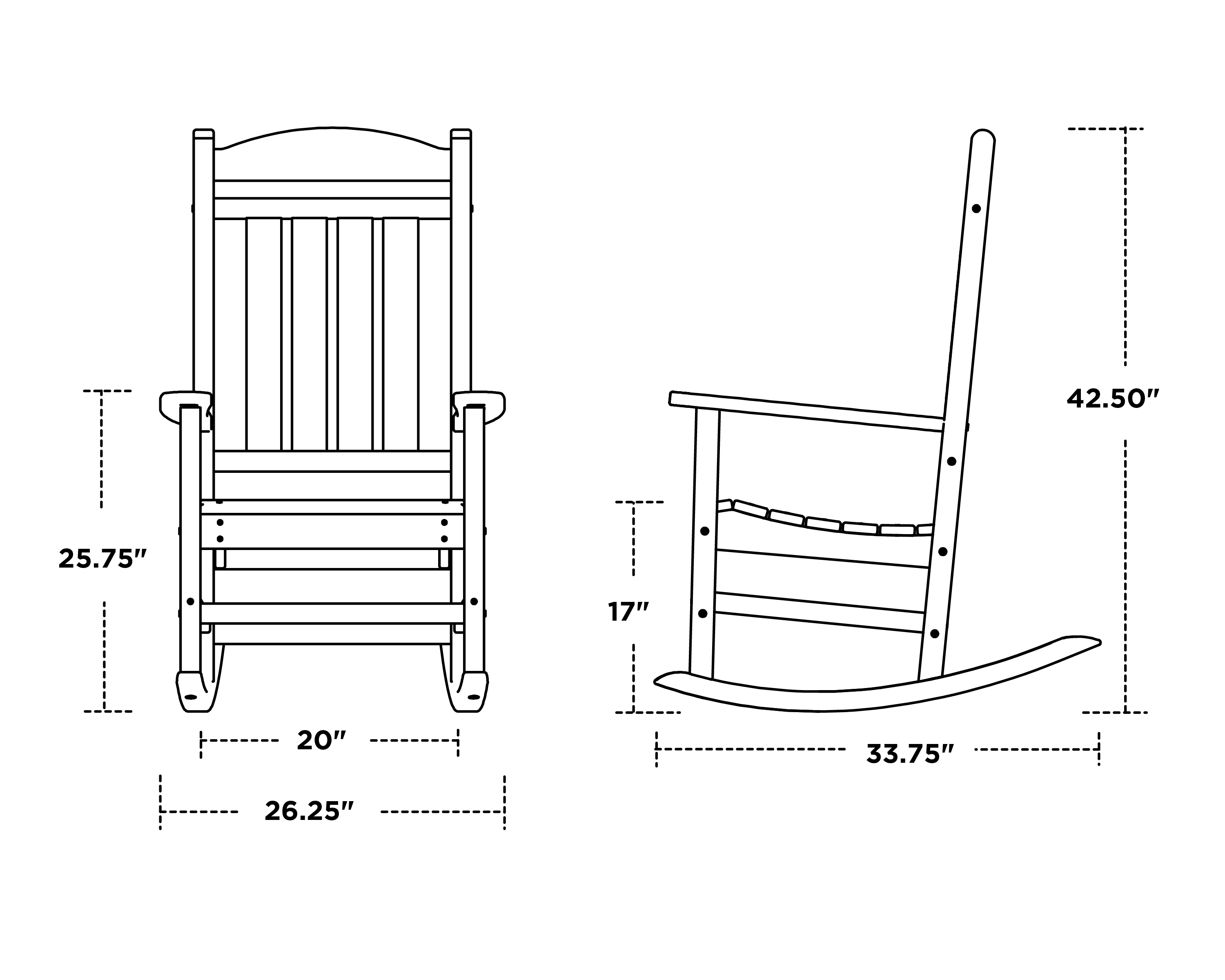

Creating a Detailed Blueprint or Sketch

A detailed blueprint or sketch of your rocking chair design is crucial for accurate construction. It helps you visualize the finished product and ensures all parts are properly sized and shaped.

- Dimensions: Clearly label the dimensions of each part of the chair, including the length, width, and thickness.

- Angles: Precisely mark the angles of the rocking chair’s curves and the seat’s back support.

- Joints: Specify the type of joints you plan to use for assembling the chair, such as mortise and tenon or dovetail joints.

- Hardware: Indicate the type and size of hardware you will need, such as screws, bolts, and nuts.

Building the Frame: How To Build A Rocking Chair From Scratch

The frame of your rocking chair is the foundation upon which the entire piece rests. Its strength and stability are paramount for a comfortable and long-lasting rocking experience. This section will guide you through the process of crafting a sturdy frame that will stand the test of time.

Cutting and Joining the Main Frame Pieces, How to build a rocking chair from scratch

The frame of a rocking chair typically consists of the seat, back, and legs. Each of these components needs to be precisely cut and joined to form a stable and functional structure.

- Seat: The seat is the platform upon which you will sit. It is typically made from a single piece of wood, with the shape and size determined by your design.

- Back: The back provides support for your spine and contributes to the chair’s overall comfort. It is often shaped with a slight curve to provide a more natural fit.

- Legs: The legs are the foundation of the chair, providing stability and allowing it to rock. They are typically made from two pairs of angled pieces that are joined at the seat and the bottom.

The process of cutting and joining these pieces requires precision and care. Using a table saw or band saw, carefully cut the wood according to your plans. Ensure the cuts are clean and accurate to ensure a smooth and sturdy final product.

Creating Sturdy and Secure Joints

The joints in your rocking chair frame are crucial for its stability and longevity. They connect the different pieces of wood and must be strong enough to withstand the stress of rocking.

- Mortise and Tenon Joints: This traditional joinery method involves cutting a rectangular hole (mortise) in one piece of wood and a corresponding projection (tenon) on the other. The tenon fits snugly into the mortise, creating a strong and secure joint.

- Dovetail Joints: These joints are known for their strength and aesthetic appeal. They involve interlocking wedge-shaped pieces that create a strong bond. Dovetail joints are often used for connecting the seat to the legs of a rocking chair.

- Gluing and Fastening: Once the joints are cut, they need to be glued and fastened together. Use a high-quality wood glue and secure the joints with screws or dowels for added strength.

Assembling the Frame

Once the individual pieces of the frame are cut and joined, you can assemble the entire structure.

- Dry Fit: Before gluing and fastening, perform a dry fit to ensure all the pieces fit together correctly. Make any necessary adjustments to ensure a smooth assembly.

- Gluing and Fastening: Apply wood glue to the joints and carefully assemble the frame. Use clamps to hold the pieces in place while the glue dries.

- Reinforcement: For added strength, consider reinforcing the frame with additional bracing or gussets. These are small pieces of wood that are added to the joints to prevent them from moving or becoming loose.

Creating the Rocking Mechanism

The rocking mechanism is the heart of your rocking chair, and it’s what gives it its signature motion. Creating a well-crafted rocking mechanism involves careful shaping and attachment of the rockers to the base of the chair, ensuring a smooth and balanced rocking experience.

Types of Rockers

The type of rocker you choose will significantly impact the rocking motion. The most common types are:

- Curved Rockers: These rockers are typically made from a single piece of wood with a gentle curve. They provide a smooth and even rocking motion, ideal for relaxing and reading.

- S-Shaped Rockers: These rockers have a more pronounced S-shape, resulting in a more vigorous and dynamic rocking motion. They are often preferred for rocking chairs used for activities like swinging a baby or rocking back and forth while working.

- Flat Rockers: These rockers are flat and straight, creating a more limited and controlled rocking motion. They are often used in rocking chairs designed for specific purposes, like rocking chairs for children.

Shaping the Rockers

- Select the Right Wood: Hardwoods like oak, maple, or cherry are ideal for rockers due to their durability and strength. Softer woods like pine or cedar can be used but may require additional reinforcement.

- Cut and Shape: Use a table saw or band saw to cut the rockers to the desired length and width. Use a jigsaw or hand saw to create the curved shape of the rockers.

- Sand Smooth: Sand the rockers to create a smooth surface and remove any sharp edges. This will ensure a comfortable rocking experience and prevent snags on clothing.

Attaching the Rockers

- Position and Mark: Position the rockers on the underside of the chair base and mark their placement with a pencil.

- Pre-Drill Holes: Pre-drill holes slightly smaller than the screws you will use to prevent the wood from splitting. This step is crucial for hardwoods.

- Secure with Screws: Use strong screws, preferably wood screws, to attach the rockers to the chair base. Ensure the screws are long enough to provide adequate support and prevent the rockers from loosening over time.

Aligning and Balancing the Rockers

- Ensure Proper Alignment: The rockers should be perfectly aligned with each other to ensure a smooth and balanced rocking motion. Check for any misalignment and adjust accordingly.

- Test the Balance: Place the chair on a level surface and test the rocking motion. The chair should rock smoothly and evenly without any wobbling or tilting. Adjust the rockers slightly if necessary to achieve balance.

- Check for Stability: Ensure the rockers are securely attached to the chair base and provide adequate support. A stable rocking motion is essential for safety and comfort.

How to build a rocking chair from scratch – Building a rocking chair from scratch can be a rewarding, albeit somewhat daunting, project. You’ll need to master the art of woodworking, navigate the complexities of creating a smooth, rocking motion, and perhaps even develop a tolerance for sawdust. But if you’re looking for a shortcut to a comfortable and stylish rocking chair, consider the sadie outdoor acacia wood rocking chair with cushion.

It’s a beautiful and practical option that might just save you from a few splinters and a lot of frustration.

Building a rocking chair from scratch is a rewarding project, but it requires careful attention to detail. You’ll need to choose the right wood, cut it precisely, and assemble it with care. Remember, the shape of the seat and the curve of the rockers will determine the comfort level, and the ideal position for ultimate relaxation is the legendary Mississippi rocking chair position , a posture known for its spine-supporting benefits.

Once you’ve mastered the art of rocking chair construction, you’ll be able to create a piece that’s not only beautiful but also perfectly tailored to your own rocking needs.